Nanofabrication

Main content start

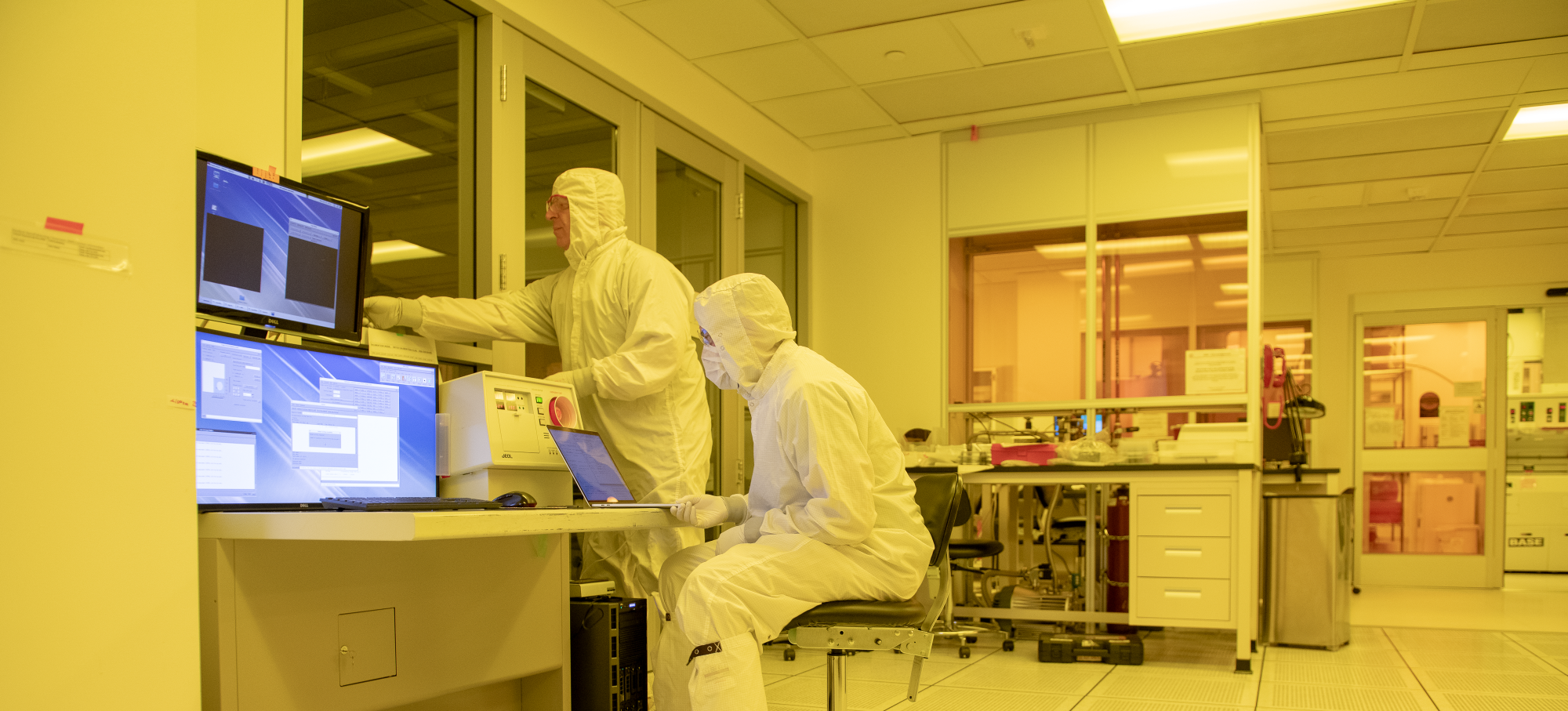

The Nanofabrication facilities feature two 2000 square feet class 100 cleanrooms located within the Spilker Building. Advanced electron beam lithography, SEM, physical vapor deposition and ion beam milling are examples of the capabilities available for nanofabrication.

The Spilker Building is home to two class 100 cleanrooms:

| Cleanroom Facilities | Locations |

| Nanopatterning Cleanroom | Spilker Basement, Room 006 Suite |

| Flexible Cleanroom | Spilker 1st floor, Room 131 Suite |

A range of equipment and capabilities exists in each of the cleanrooms. The following lists the tools available: